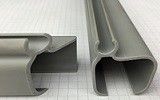

Materials

We use different materials for custom extrusions including:

PVC - Polyvinyl chloride

- PVC – RIGID Extremely versatile general purpose Calcium Zinc stabilised medium impact rigid PVC for internal and external use.

- PVC – FLEXIBLE General purpose Calcium Zinc stabilised flexible PVC for internal use.

- PVC – TRANSPARENT Clear rigid PVC.

- PVC – FOOD GRADE General purpose Calcium Zinc stabilised PVC suitable for food contact applications.

- PVC – NITRILE Flexible PVC with good resistance towards oil, fuel and acid which is often used in the automotive industry.

ABS - Acrylonitrile Butadiene Styrene High impact, lightweight and strong rigid material with good adhesive properties. Often used in automotive and aeronautical industries.

Polypropylene Versatile rigid material which is lightweight with high tensile strength and high heat resistance.